What is the term AQL and what is the function of AQL tables?

Surely, previously in our publications you have seen the term AQL reflected as part of the quality control process.

Next, we will delve into it. When employing the services of quality control companies, an important factor to understand is the standard used to select a sample for visual or appearance review. The most widely used standard for product inspections is ISO 2859-1 (ANSI / ASQC Z1.4-2003). This standard uses the concept of AQL or Acceptable Quality Limit.

The technical definition of AQL (Acceptable Quality Limit) is “the maximum percentage of defects that can be considered satisfactory for the chosen sample”.

First, a sample is selected based on the AQL tables and then inspected for defects.

Defects are classified into 3 categories: minor, major, and critical. Although the criteria may vary between clients, the following is generally considered:

- Minor defects: represent a discrepancy with respect to what is established, but do not affect at all the usability of an object.

- Major defects: are those that can cause a failure with respect to the functionality of the product.

- Critical defects: Are those that are considered dangerous or unsafe.

According to the number of defects found for each category and the number of defects allowed (figures given by the AQL tables), your inspection company may suggest accepting or rejecting the shipment.

How are AQL tables used?

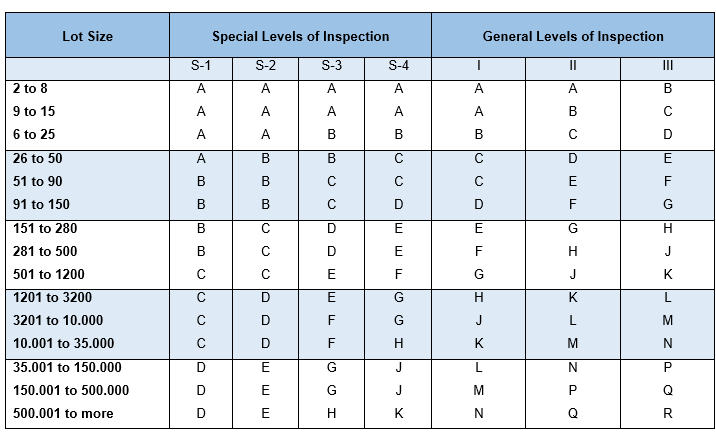

The AQL tables will help determine the size of the sample to be inspected according to the total order quantity and its severity level. You can choose between levels I, II or III, with level III being the most rigorous and level I the least rigorous.

In order to determine the size of the sample, it is important to look at the first table and be able to see on the left side the range of total units of the order.

At the top of the second table are defect levels ranging from 0 to 6.5. You can decide what level you want to apply for each type of defect: critical, major and minor. Most importers choose 0 / 2.5 / 4 defect levels but 0 / 1.5 / 2.5 levels can also be chosen if necessary.

Using the standard 0 / 2.5 / 4 defect level on a sample of 200 units means that if there are more than 0 critical defects, 10 major defects and 14 minor defects, the shipment must be rejected.

In this way, it should be noted that the final decision belongs to the client. Most importers will discuss the inspection results with their supplier in order to improve current processes. In case the inspection results are very close to the AQL limits, it is important to check if this level of defects is acceptable or not for the company.

Details always count and doing things the right way costs nothing.

At Esasia, we do everything we can to help our clients achieve their goals successfully.